In a paper published in the Journal of Food Engineering, researchers introduced a computer vision (CV) system synchronized with a collaborative robot (cobot) to objectively assess the rehydration quality of infant formula (IF) by measuring foam height, sediment height, and white particles.

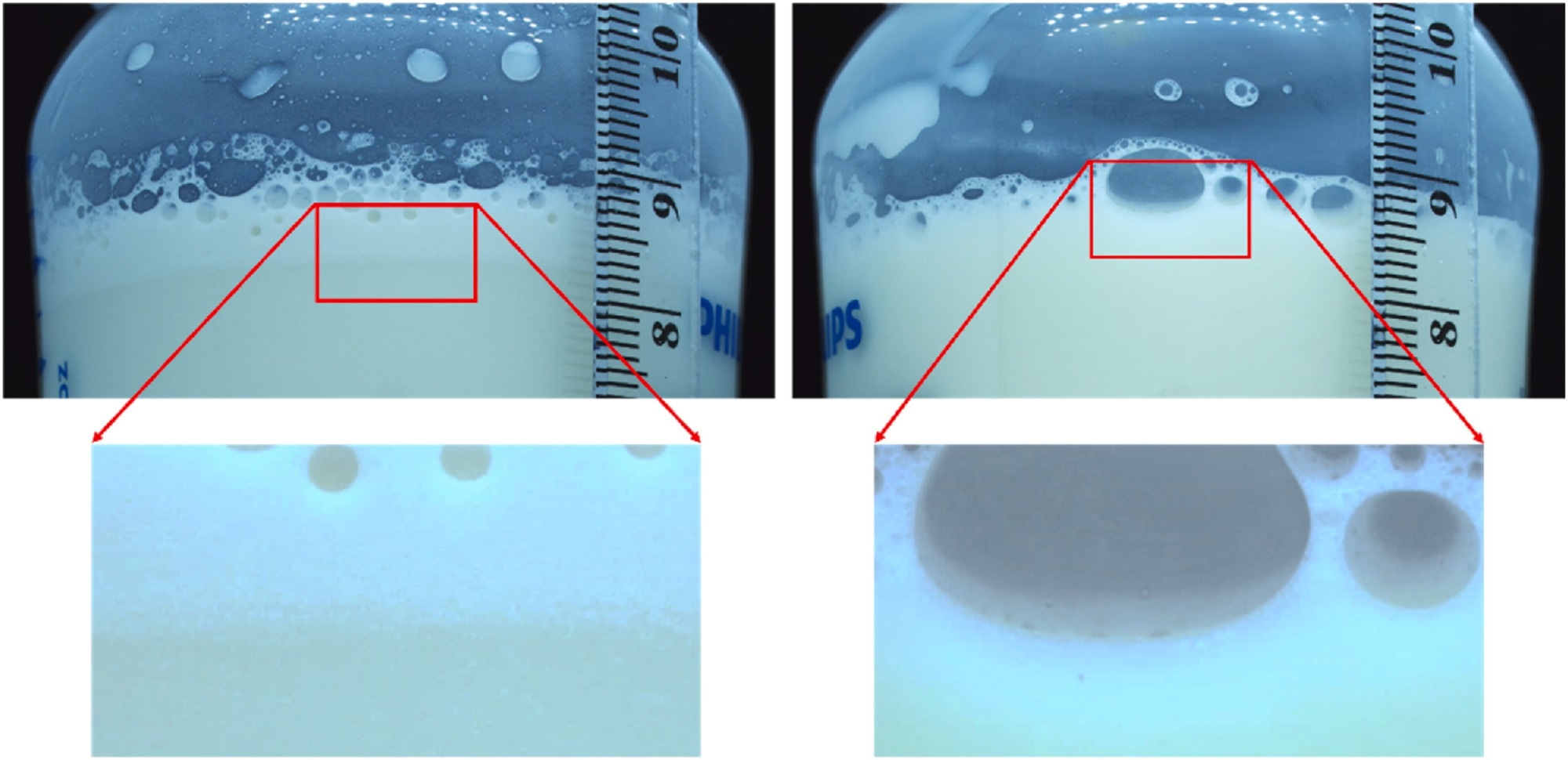

Bubble size and foam-mixture boundary in different mixtures (left: mixture C1 with small bubbles, right: mixture P1 with elliptical bubbles) – mixtures were prepared and photographed automatically using the platform. Image Credit: https://www.sciencedirect.com/science/article/pii/S0260877424002954

Bubble size and foam-mixture boundary in different mixtures (left: mixture C1 with small bubbles, right: mixture P1 with elliptical bubbles) – mixtures were prepared and photographed automatically using the platform. Image Credit: https://www.sciencedirect.com/science/article/pii/S0260877424002954

Using two robotic agitation methods and analyzing 24 stage-1 powders, the system's estimates of foam height, sediment height, and particle count showed close agreement with independent human ratings. This platform demonstrates the potential for objective rehydration testing and monitoring changes in foam and sediment over time.

Related Work

Past work has highlighted the need for objective methods to assess the rehydration quality of IF powders, which are typically evaluated subjectively. Recent studies have developed CV systems integrated with collaborative robots (cobots) to measure foam height, sediment height, and particle count. These systems use advanced imaging techniques and algorithms to provide consistent, non-destructive assessments of rehydration attributes.

Automated Rehydration Analysis

The study employed a dual-arm YuMi cobot and a custom vision system to automate the rehydration of IF powders and assess rehydration attributes. The cobot, designed to mimic human agitation techniques, was integrated with a 21-megapixel industrial camera and a cubic lightbox to ensure consistent and uniform lighting. The vision system, placed inside the lightbox, captured images of rehydrated mixtures in a commercial baby bottle from multiple angles. This setup minimized disturbances and maintained conditions similar to those experienced by end users.

The rehydration involved two agitation styles—swirl and shake—with each powder sample mixed for 15 seconds. The cobot performed the rehydration and captured images. It evaluated the rehydration attributes using three CV algorithms: one for foam height, one for sediment height, and one for white particle count. Images were taken at six different viewpoints for each mixture, with a specific protocol to allow the mixture to stabilize before capturing the images.

To validate the effectiveness of the CV system, human participants rated the same images to compare results. Eight participants assessed images for foam height, sediment height, and white particle count using a standard operating procedure. The comparison involved statistical analyses, including Pearson correlation coefficients, bland-Altman plots, and Krippendorff’s alpha, to evaluate the agreement between human and CV estimates. Data analysis was conducted using R software, with results presented through visualizations and statistical tests to assess the accuracy and reliability of the CV platform.

CV vs. Human

The study revealed that commercial powders had larger particle sizes than pilot plant powders, influencing their rehydration properties. The team compared dissolved solids (DS) and total solids (TTS), showing that Shake agitation resulted in higher DS due to its more energetic nature, leading to smaller particle sizes and less sediment than Swirl agitation. Variations in TTS and DS affected the mixtures' perceived rehydration efficiency and sediment levels.

When comparing CV and human ratings, there was a high correlation between foam height (0.82) and sediment height (0.77) when averaged over multiple viewpoints. However, individual image assessments showed less agreement due to differences in measurement precision and varying foam conditions. The CV system's foam and sediment estimates aligned well with human ratings, although discrepancies were noted in less consistent lighting conditions.

For white particle ratings, the CV's particle counts correlated moderately with human ratings, with improved agreement when categorized logarithmically. The agitation method did not significantly affect white particle ratings. Averaging ratings across multiple imaging rounds provided a higher agreement between CV and human ratings than individual images. Krippendorff's Alpha indicated moderate agreement between human raters, suggesting that CV and human ratings exhibit comparable variability.

The study highlights the practical advantages of employing automated CV systems for quality assessment in powdered formula rehydration. The results suggest that CV can effectively capture and quantify key attributes such as foam height and sediment levels, offering a reliable alternative to human evaluations.

Automated systems' integration improves the consistency and objectivity of measurements and allows for more comprehensive analysis across various agitation methods and powder types. Future research could focus on refining the CV algorithms to address the observed discrepancies and enhance measurement accuracy, potentially leading to more standardized and efficient quality control processes in the industry.

Conclusion

To sum up, this research successfully developed an automated platform for rehydrating powdered formulas and objectively assessing foam height, sediment, and white particles. The CV estimates for these attributes correlated well with human ratings, although improvements are needed in foam and white particle algorithms. The study demonstrated that energetic agitation enhances rehydration and reduces sedimentation, while further research is planned to refine CV accuracy and validate results against traditional methods.

Article Revisions

- Aug 15 2024 - Fixed broken journal paper link.