They adapted the YOLO architecture to tackle challenges in large, high-resolution microscopy images, particularly addressing the need for high recall in detecting vessel elements, a key feature for hardwood species identification. The results showed that WoodYOLO outperformed state-of-the-art models by achieving a 12.9% improvement in the F2 score compared to YOLOv10. This advancement in automated wood cell type localization aids regulatory compliance, sustainable forestry, and biodiversity conservation efforts.

Related Work

Past work on automated wood species identification in microscopic images has explored deep learning techniques, including YOLO for vessel element detection.

One approach used YOLOv7 for localization and CNNs for classification, but room for improvement remains. While transformer-based models like DETR have demonstrated promise in some tasks, they face significant challenges in this domain, such as higher time complexity and slower training speeds, making them less suitable for large-scale, high-resolution images.

Recent adaptations of YOLO for high-resolution images have yielded marginal improvements, often making only minor changes to the original architecture. In contrast, WoodYOLO was developed from scratch, incorporating components from different YOLO versions to better address the specific challenges of vessel detection in wood fiber microscopy.

YOLO-based Vessel Detection Framework

The study focused on frequently processed woods cultivated in plantations for pulp, paper, and fiberboard production, such as poplar and eucalypt, with the exact genera provided. Vouchered specimens from the Thünen Institute's wood collection and other documented sources were used as reference material.

The wood tissue was macerated following Franklin's method, with at least three macerates per genus. Each macerate resulted in 20 slides, ten of which were stained using the Alexander Herzberg solution and ten with nigrosine.

The main aim was to detect vessel elements in microscopic images, the water-conducting cells that exhibit distinct morphological features setting them apart from other cell types like fibers or parenchyma. This is a key feature for automating hardwood species identification in fibrous materials.

The customized YOLO model addressed challenges with large image sizes and high recall, outperforming models like DETR in real-world applications. The model excluded classification to focus solely on detection, enabling efficient feature extraction and improved recall performance.

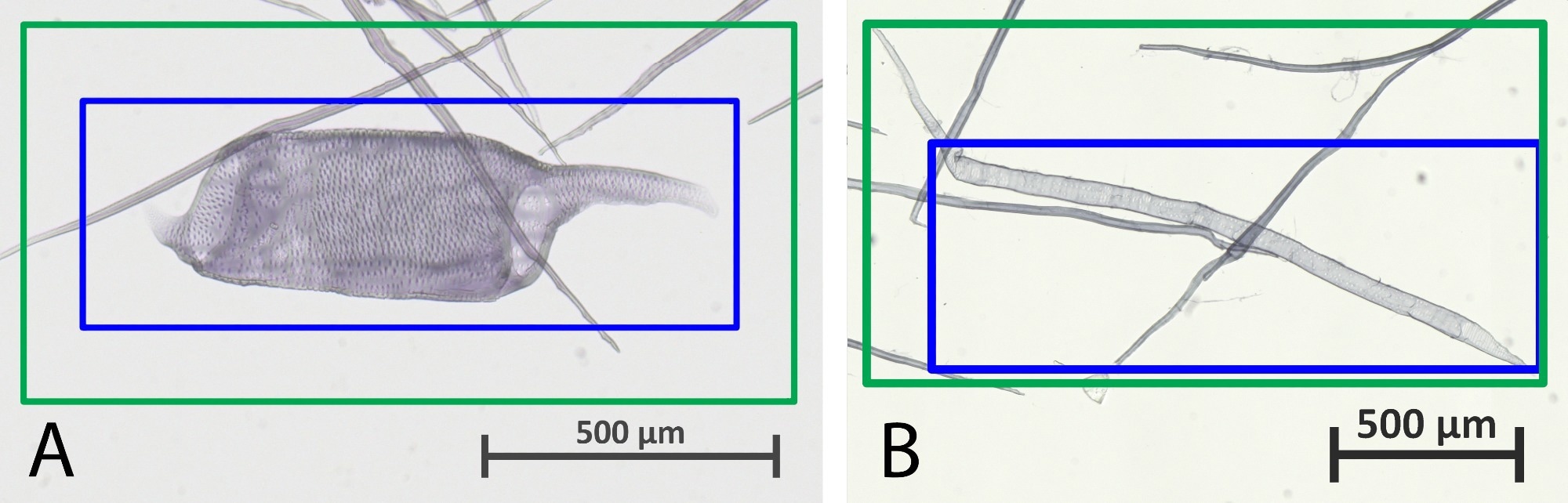

Comparison of predicted bounding boxes (blue) and ground truth boxes (green). A high IoU threshold can result in both predicted boxes being rated as errors. (A) The overlap is below 0.5. Due to incorrect annotations, the predicted bounding boxes are sometimes more accurate. (B) Imperfect prediction as the end of the object (vessel element) is not detected.

Comparison of predicted bounding boxes (blue) and ground truth boxes (green). A high IoU threshold can result in both predicted boxes being rated as errors. (A) The overlap is below 0.5. Due to incorrect annotations, the predicted bounding boxes are sometimes more accurate. (B) Imperfect prediction as the end of the object (vessel element) is not detected.

By adapting YOLO for vessel detection and excluding classification, components from various YOLO versions enhanced the framework's accuracy.

The model's architecture consisted of a backbone for efficient feature extraction from large microscopic images, followed by a neck that combined multi-scale feature maps. The neck, based on YOLOv7-tiny, was selected for its memory efficiency, crucial for training at higher resolutions compared to typical object detection tasks. Several backbones were tested, and YOLOv7-tiny showed better results.

The detection head produced outputs for the bounding box coordinates and object confidence, using simple regression and classification losses to optimize performance. The loss function emphasized Generalized IoU (GIoU), which yielded better results in improving recall.

To further optimize detection, the study explored techniques like center sampling and multi-positives, where neighboring grid cells were also used to match ground truth boxes. However, these techniques did not lead to significant improvements for this specific task.

Additional approaches, such as deep supervision, anchor boxes, and non-maximum suppression (NMS)-free detection, were also tested but did not yield significant improvements. The final model prioritized simplicity while achieving the highest recall by optimizing specific configurations for vessel element detection. Training strategies like mosaic augmentation and gradient accumulation were excluded due to their minimal impact on the results.

Optimized Vessel Detection Model

The authors evaluated WoodYOLO on a dataset designed to automate detecting and identifying vessel elements in hardwood species, a crucial task for classifying wood species. Vessel elements, essential for water conduction in hardwoods, have distinct morphological features that set them apart from other cell types like fibers or parenchyma.

The dataset comprises high-resolution images of hardwood samples captured with a ZEISS Axioscan 7 microscope. These images were downscaled to improve training efficiency, with 767 annotated images used for training and validation. The evaluation focused on F2 scores at a fixed IoU threshold of 0.3, comparing the performance of various detection models.

Regarding detection performance, the customized WoodYOLO model outperformed several other YOLO variants, achieving an F2 score of 0.848, which was higher than models like YOLOv7 and YOLOv10. The authors also evaluated different backbone networks, with VGG11-bn providing the highest individual backbone F2 score of 0.8316, although the full WoodYOLO model outperformed all alternatives.

The authors highlighted the effectiveness of reducing image resolution to 2048 pixels for training, which maintained performance while minimizing memory requirements. Removing constraints on object width and height also improved detection, highlighting the effectiveness of their customized approach.

The results emphasize the importance of designing specialized detectors for tasks that diverge from standard object detection benchmarks, as they can better meet the specific requirements of the problem.

Conclusion

To sum up, WoodYOLO, a novel object detection algorithm optimized for microscopic wood fiber analysis, outperformed state-of-the-art models like YOLOv10 and YOLOv7 in detecting vessel elements with significantly higher F2 scores.

The evaluation highlighted the effectiveness of customized architecture and training techniques, particularly the exclusion of complex configurations like anchor boxes and the emphasis on simplicity. This automated wood species identification advancement has important implications for sustainable forestry practices and biodiversity conservation.

*Important notice: arXiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as definitive, used to guide development decisions, or treated as established information in the field of artificial intelligence research.

*Important notice: arXiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as definitive, used to guide development decisions, or treated as established information in the field of artificial intelligence research.

Journal reference:

- Preliminary scientific report.

Nieradzik, L., et al. (2024). WoodYOLO: A Novel Object Detector for Wood Species Detection in Microscopic Images. ArXiv. DOI: 10.48550/arXiv.2411.11738, https://arxiv.org/abs/2411.11738