In a recent article published in the journal Scientific Reports, researchers comprehensively investigated how machine learning (ML) algorithms could predict the corrosion rate of steel buried in soil. They aimed to identify the limitations of existing state-of-the-art models and proposed a new ML-based approach for more accurate predictions.

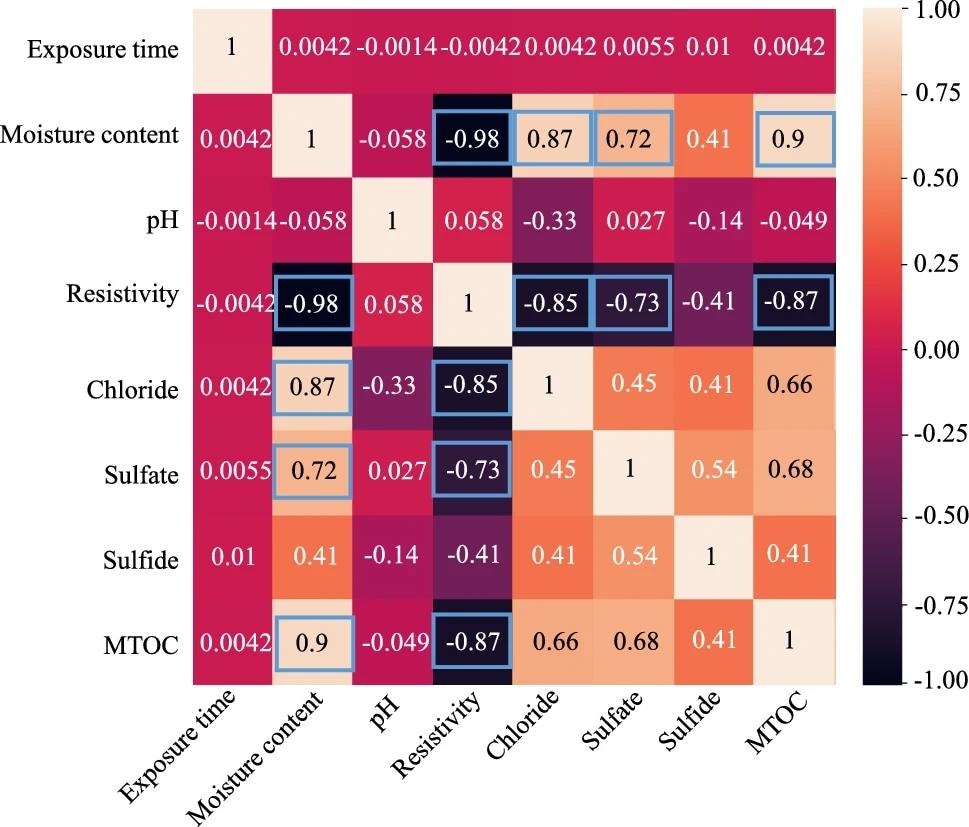

Pearson correlation coefficient of each variable. Values marked with the rectangle demonstrate a strong correlation. Image Credit: https://www.nature.com/articles/s41598-024-68562-w

Pearson correlation coefficient of each variable. Values marked with the rectangle demonstrate a strong correlation. Image Credit: https://www.nature.com/articles/s41598-024-68562-w

Background

Corrosion of steel buried in the soil is a major concern for various engineering projects like foundations, pipelines, and different types of infrastructure (buildings, bridges, etc.). The corrosion process is a complex phenomenon that can be affected by many factors, including soil composition, moisture, potential of hydrogen ions (pH), resistivity, and corrosive ions like chloride, sulfate, and sulfide. These factors interact in complicated ways, making it challenging to predict corrosion rates with traditional methods.

Traditional methods often use empirical models, which have limited accuracy due to the complex nature of corrosion and the difficulty of capturing all influencing factors. These models usually focus on only a few factors and may not fully consider the dynamic interactions in soil environments.

About the Research

In this paper, the authors aimed to develop a more accurate and robust model for predicting soil-buried steel corrosion using ML techniques. They employed three widely used ML algorithms: random forest (RF), multilayer perceptron (MLP), and support vector regressor (SVR). These algorithms were trained on a comprehensive dataset of soil parameters and corresponding corrosion current densities obtained from laboratory experiments.

The dataset included eight input variables: moisture content, pH, resistivity, chloride content, sulfate content, sulfide content, exposure time, and mean total organic carbon (MTOC). The output variable was the corrosion current density, a key indicator of corrosion rate.

The study followed a systematic methodology for developing and evaluating the ML models. This involved data preprocessing, feature engineering, data splitting, hyperparameter tuning, and model training and evaluation. The researchers used a five-fold cross-validation technique to assess the model's performance and prevent overfitting. The performance metrics used for evaluation included root mean squared error (RMSE), mean absolute error (MAE), coefficient of determination (R²), and mean absolute percentage error (MAPE).

Research Findings

The outcomes showed that the RF model consistently outperformed the SVR and MLP models in forecasting soil-buried steel corrosion current density. The RF model achieved the highest accuracy, with an R² value of 0.987 and an RMSE of 0.01095 A/m². This indicates that the RF model can accurately capture the complex relationships between soil parameters and corrosion rate.

Furthermore, the study identified electrical resistivity as the most important feature for predicting corrosion current density. This result aligns with previous research highlighting the importance of soil resistivity in influencing corrosion rates. The authors also conducted a sensitivity analysis to understand the impact of individual soil parameters on corrosion rates. They found that resistivity, MTOC, moisture content, and chloride content had the most significant influence on corrosion current density.

Applications

This research has important implications for enhancing the durability and safety of soil-buried structures. By providing more accurate estimates of corrosion rates, the model allows engineers to design more durable structures, optimize maintenance schedules, and reduce the risk of failure. Engineers can use the model's predictions to select materials and design structures that are better suited to specific soil conditions and anticipated corrosion rates, leading to longer-lasting, more corrosion-resistant infrastructure.

Additionally, the model helps forecast when maintenance is needed, which can prevent costly repairs and ensure the long-term integrity of the infrastructure. This results in more efficient maintenance practices and reduced overall management costs. Finally, accurate corrosion rate predictions enable engineers to identify potential failure points and take proactive measures to mitigate risks, thereby improving the safety and reliability of infrastructure and reducing the likelihood of accidents and disruptions.

Conclusion

In summary, ML techniques proved effective, robust, and cost-efficient for accurately forecasting the corrosion of steel embedded in soil. The RF model, in particular, surpassed traditional empirical models, showcasing ML’s strength in managing complex relationships and large datasets. The study emphasized the importance of considering multiple soil parameters and their interactions in corrosion predictions. Insights from feature selection and sensitivity analysis could inform future advancements in corrosion mitigation strategies.

Moving forward, the researchers recommended using advanced ML and optimization techniques to enhance corrosion forecasting and improve the durability and safety of soil-buried structures. This includes adding more soil parameters, such as temperature and particle size, to the model and exploring newer ML algorithms. The research also emphasized the need for ongoing data collection and analysis to refine ML-based corrosion prediction models.