In a recent paper published in the journal Scientific Reports, researchers explored the use of deep learning and particle swarm optimization (PSO) to enhance the obstacle recognition and avoidance capabilities of inspection robots in power plants.

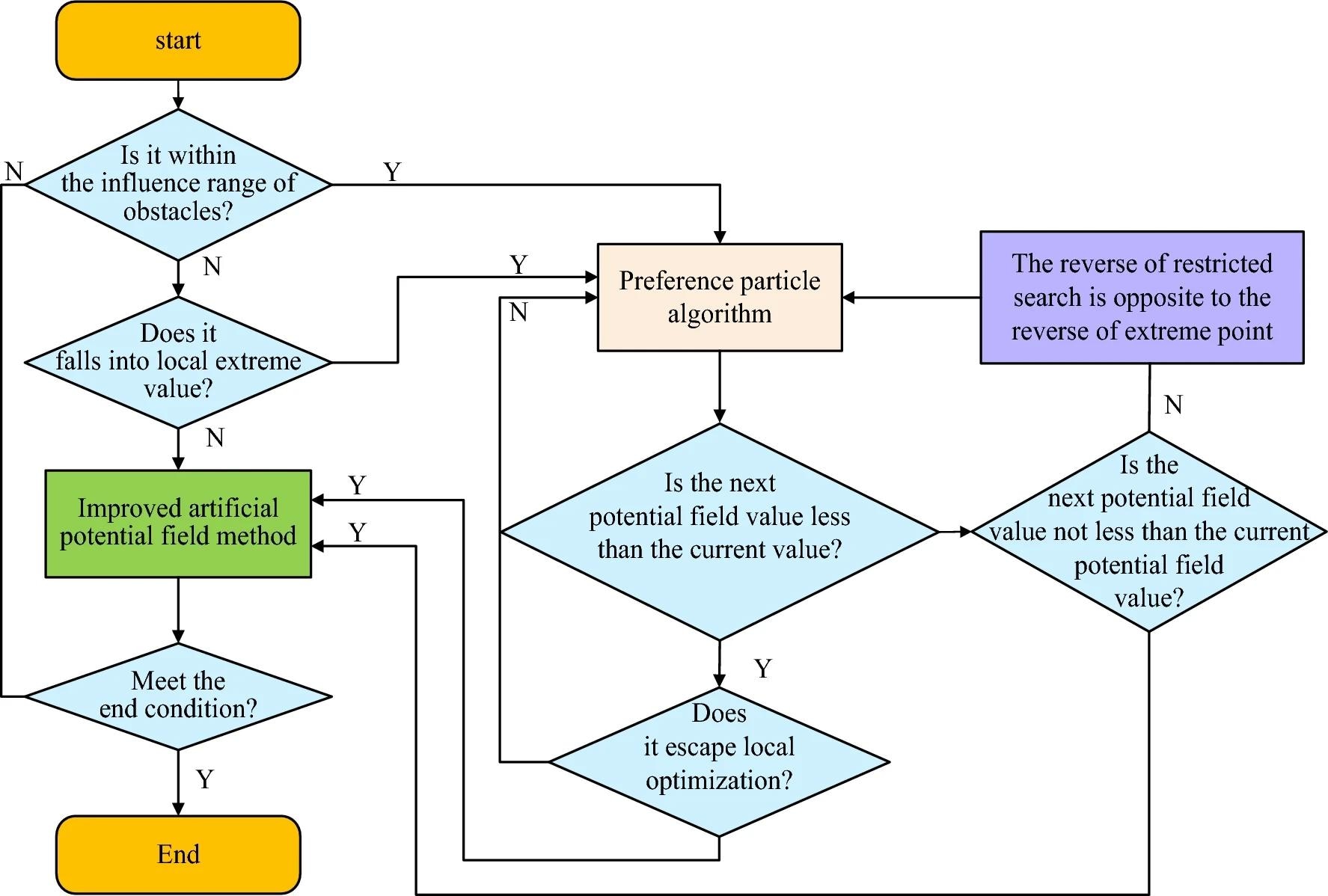

Flow chart of hybrid path planning based on preferred particle swarm optimization and improved artificial potential field. Image Credit: https://www.nature.com/articles/s41598-024-56795-8

Flow chart of hybrid path planning based on preferred particle swarm optimization and improved artificial potential field. Image Credit: https://www.nature.com/articles/s41598-024-56795-8

They proposed an improved convolutional recurrent neural network (CRNN) model for obstacle recognition and an artificial potential field method (APFM) based PSO algorithm for path planning and obstacle avoidance.

Background

Power plants are complex and potentially dangerous environments that require regular inspection and maintenance to ensure their safety and efficiency. However, manual inspection has many limitations and risks, such as high cost, low efficiency, and exposure to hazardous conditions. Therefore, the use of robots can improve efficiency and prevent personnel from being exposed to potentially dangerous environments.

One key challenge for inspection robots is accurately recognizing and avoiding obstacles in the power plant environment. Obstacle recognition and avoidance are essential for ensuring the safety and reliability of inspection robots. Traditional methods often rely on pre-determined rules and paths, which lack flexibility and adaptability to dynamic environments. Recent advances in artificial intelligence (AI) emphasized the development of more sophisticated methods for obstacle recognition and avoidance.

About the Research

In this article, the authors developed an innovative obstacle recognition and avoidance device for power plant inspection robots, which comprises two primary components: an obstacle recognition model and an obstacle avoidance model.

The obstacle recognition model relies on an enhanced CRNN, capable of effectively processing spatial and temporal data. It incorporates three layers: a convolution layer for feature extraction from input images, a bidirectional long short-term memory (Bi-LSTM) layer for analyzing feature sequences and making initial predictions, and a transcriptional layer for converting predictions into the final recognition sequence. To address one-to-many mappings between input and output sequences, the study employs a connectionist temporal classification (CTC) algorithm.

The obstacle avoidance model is founded on an artificial potential field method (APFM) based PSO algorithm, which merges the strengths of both approaches. PSO is a metaheuristic algorithm inspired by natural swarms, that efficiently search for optimal solutions to complex problems. APFM treats targets and obstacles as generators of a potential field, guiding the robot within it. PSO dynamically adjusts particle acceleration coefficients based on the current environment to optimize the robot’s path. It also integrates a preference-based strategy to navigate local optima and obstacle boundaries effectively.

Additionally, the researchers conducted a series of experiments to assess the proposed system's performance in obstacle recognition accuracy, path planning efficiency, and multi-scene inspection performance. They compared it with traditional methods like the basic CRNN model and the standard PSO algorithm.

Research Findings

The authors observed significant improvements in obstacle recognition accuracy with the proposed CRNN model compared to the traditional one. The highest accuracy on the training dataset jumped from 0.873 to 0.962, with validation accuracy reaching 0.978. This surpassed the traditional model's accuracy of 0.907. This leap in performance was likely due to the CRNN's ability to capture long-term dependencies within the image sequences. By considering both past and future visual information, the model could make informed predictions about the appearance of the obstacle.

The proposed PSO algorithm also demonstrated superior efficiency in path planning compared to traditional PSO and those incorporating genetic algorithms (GA-PSO). It reached a stable state in just 40 iterations with a low operation error of 0.22. Traditional GA-PSO and PSO algorithms needed 73 and 84 iterations, respectively, with higher errors (0.29 and 0.35). This improvement could be attributed to the adaptive nature of the proposed algorithm. By dynamically adjusting particle acceleration coefficients based on the real-time environment, the PSO algorithm optimized its search process, leading to faster convergence and a more efficient path.

Applications

The proposed system has potential applications in various industrial scenarios, such as manufacturing, construction, and energy production. It can improve the efficiency and safety of inspection and maintenance tasks, as well as reduce the cost and risk of human labor. Additionally, it can be adapted to different types of robots, such as mobile robots, aerial robots, and underwater robots, to perform inspection tasks in different environments.

Conclusion

In summary, the novel approach for obstacle recognition and avoidance demonstrated effectiveness in inspecting power plants, surpassing traditional methods in accuracy, efficiency, and adaptability. Its implementation could elevate the automation and intelligence of power plant patrol inspection, thereby enhancing the safety and efficiency of power plant operations.

Moving forward, the researchers suggested several directions for future work. They recommended exploring robust obstacle recognition models capable of handling challenging environments, integrating real-time obstacle detection capabilities, and developing path planning algorithms capable of dynamically adjusting to changing obstacle configurations.