In an article published in the journal Scientific Reports, researchers from Central South University of Forestry and Technology, China, proposed a new algorithm called coordinate-attention-enhanced defect inspection you only look once (CDI-YOLO) for detecting defects in printed circuit boards (PCBs). They aimed to balance high detection accuracy, fast detection speed, and a few network model parameters for practical PCB defect detection systems.

CA module. https://www.nature.com/articles/s41598-024-57491-3

CA module. https://www.nature.com/articles/s41598-024-57491-3

Background

PCBs are the backbone of electronic devices, connecting components and facilitating signal transmission. During PCB manufacturing, defects can occur, falling into two main categories: functional defects (which directly affect PCB performance) and appearance defects (which impact aesthetics).

Common defects include missing holes, mouse bites, open circuits, shorts, spurs, and spurious copper. Ensuring the quality of PCBs is crucial for the reliability and performance of electronic products because defects in PCBs can lead to malfunctions or failures in electronic devices. Detecting defects in PCBs is a complex task that requires precision and speed to maintain high production standards.

Historically, manual visual inspection, functional testing, and inline instrumentation were used for defect detection. However, these methods have limitations such as visual fatigue, slow speed, and high costs. Therefore, developing efficient and accurate methods for PCB defect detection is of great importance.

Deep learning-based approaches have shown promising results in this field. Automated optical inspection (AOI) emerged as a non-contact method based on machine learning and image processing. Among AOI methods, CDI-YOLO stands out for its accuracy and efficiency.

About the Research

In the present paper, the authors designed CDI-YOLO, an innovative PCB defect detection algorithm, to address the limitations of existing methods. They selected lightweight YOLO version 7 (YOLOv7)-tiny network model as the baseline due to its lightweight nature and real-time performance. The YOLOv7-tiny model is a variant of the YOLOv7 object detection algorithm, which includes models with different widths and depths for different graphical processing units (GPUs). The researchers made improvements to the baseline model to enhance its performance in PCB defect detection.

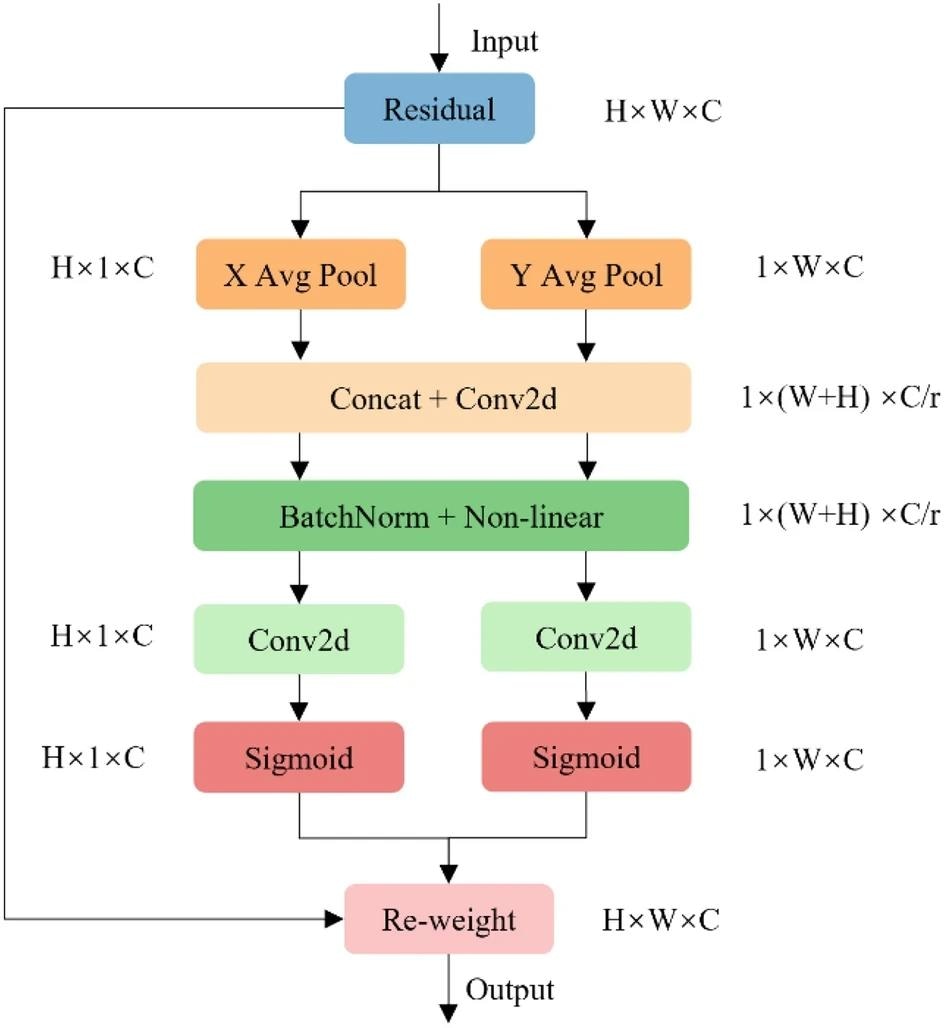

The CDI-YOLO network model incorporated the coordinated attention (CA) module into the efficient lightweight attention network (ELAN) module of YOLOv7-tiny. The CA module is an attention mechanism used in computer vision tasks to improve model performance by enhancing feature representation. In PCB defect detection, the CA module enhances the YOLOv7-tiny network model's ability to extract defect information from PCBs, thereby improving the accuracy of defect detection.

Additionally, the authors also replaced part of the common convolution in YOLOv7-tiny with depthwise separable convolution (DSConv) to reduce model complexity and improve detection speed. Furthermore, they employed center-intersection over union (Inner-CIoU) as the regression loss function, which leverages auxiliary bounding boxes to advance the model's bounding box regression speed.

Moreover, the proposed network model was evaluated through experiments and compared with existing mainstream methods such as YOLO version 3 (YOLOv3), YOLO version 4 (YOLOv4), and YOLOv7-tiny. The performance of the models was analyzed based on various metrics, including precision, recall, mean average precision (mAP), parameters, giga floating point operations per second (GFLOPs), and frames per second (FPS).

Research Findings

The outcomes showed that the CDI-YOLO network model outperformed the other models in terms of detection accuracy. It achieved the highest mAP of 98.3% compared to the existing methods. In terms of model parameters, CDI-YOLO had 5.8 million parameters, which were higher than YOLOv7-tiny but with no or negligible difference. The detection speed of CDI-YOLO was lower than YOLOv7-tiny, with a speed of 128 FPS. The proposed model could be applied to detect defects in PCBs, ensuring the production of high-quality electronic devices. Furthermore, its improved balance between detection accuracy and speed made it suitable for real-time defect detection applications.

The application can extend beyond the realm of PCB defect detection, offering promising applications in various industries that rely on automated inspection systems. The outstanding performance of the algorithm makes it a valuable tool for quality control in the electronics industry, automotive production, pharmaceuticals, and other sectors where precision and reliability are paramount. By automating defect detection processes and minimizing human intervention, this technology has the potential to streamline operations, reduce costs, and enhance overall product quality.

Conclusion

In summary, the novel model proved to be effective and efficient for accurately detecting defects in PCBs. It demonstrated improved performance in terms of detection speed and model parameters. The study highlighted the importance of balancing these factors in deep learning-based methods for defect detection.

The researchers acknowledged the limitations and challenges and recommended directions to further enhance the algorithm's efficacy. They proposed exploring weakly supervised learning methods, such as unlabeled data utilization, weak labeling, and semi-supervised learning approaches. These techniques have the potential to improve the algorithm's performance and versatility while reducing the demand for large amounts of annotated or fully labeled data, thereby decreasing costs and enhancing detection capabilities.

Additionally, the paper highlighted investigating novel optimization strategies to further optimize detection efficiency. Moreover, conducting real-world validation studies was suggested to assess the algorithm's effectiveness in practical industrial settings. Such studies are crucial for evaluating the algorithm's performance outside controlled laboratory environments and ensuring its suitability for real-world applications.