In a paper published in the journal Communications Engineering, researchers explored in-sensor computing's potential for machine learning (ML) in compact, energy-constrained devices like wearables and Internet of Things (IoT) gadgets. They overcame challenges by utilizing reservoir computing within the physical system's degrees of freedom.

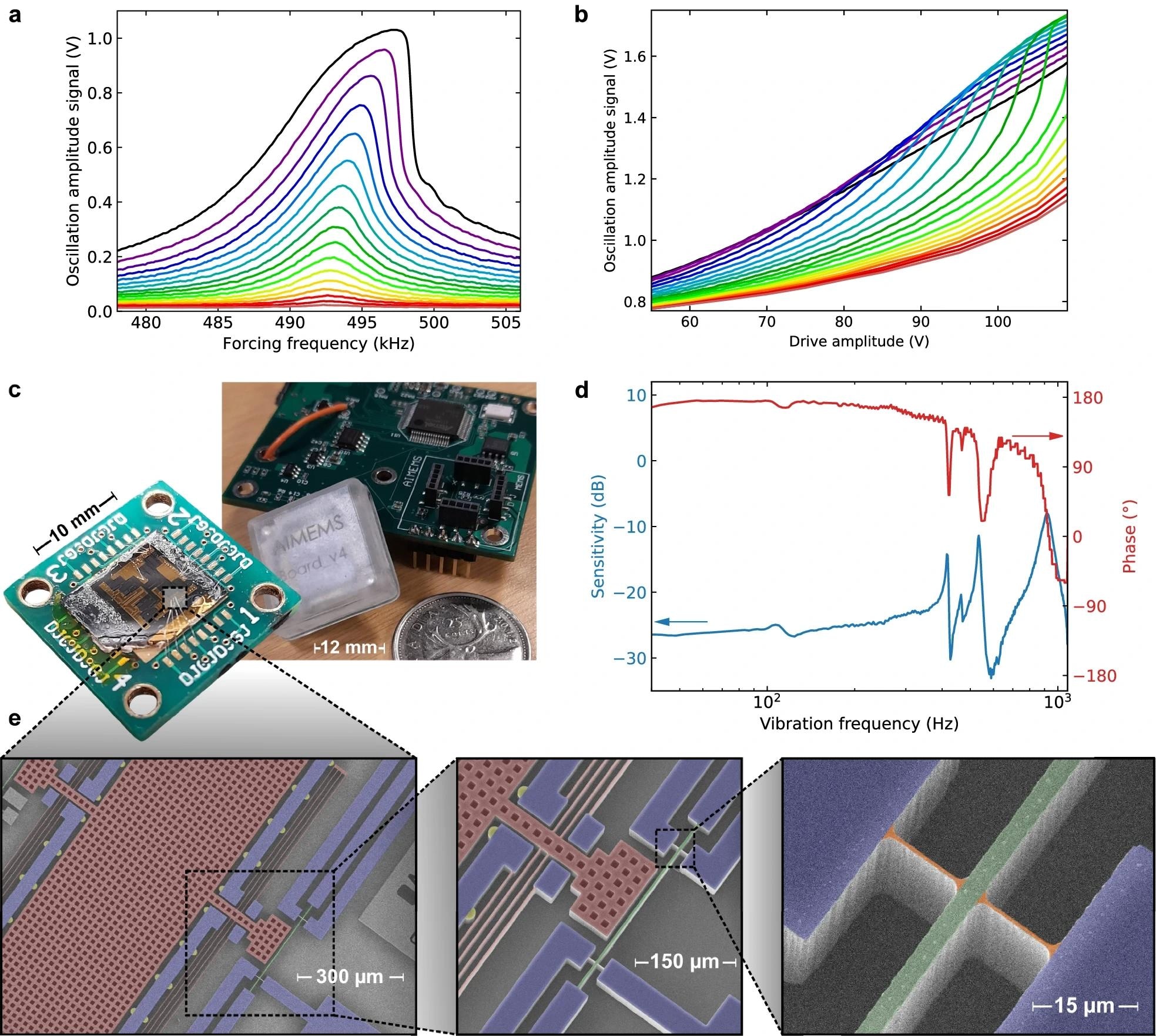

Mechanical response of the gait analysis system.a Frequency response curves for the silicon beam for a drive voltage amplitude that is increased from 30 V (red) to 109 V (black) in steps of 5 V (up to 105 V, black curve at 109 V). The Duffing stiffening nonlinearity of the silicon beam can be observed in the asymmetry of the frequency response curves. b Drive amplitude voltage sweeps for the silicon beam for a forcing frequency that is increased from 493.4 kHz (black curve) to 501.0 kHz (red curve) in steps of 400 Hz. These sweeps show that the deviation from the linear regime is increased as the drive voltage amplitude and forcing frequency are increased. c Photographs of the packaged MEMS and its main electronics board. d Inertial response of the MEMS, where the sensitivity is displayed as the amplitude of the oscillation signal (in V) per unit of acceleration applied (in standard gravity g), converted to decibels (dB) using a reference level of 1 V per g (at 0 dB). e Manually colored scanning electron microscope images of a device (red: inertial mass and spring suspension, blue: anchors, green: clamped beam, yellow: inertial mass stoppers, orange: strain gages). https://www.nature.com/articles/s44172-024-00193-5

Mechanical response of the gait analysis system.a Frequency response curves for the silicon beam for a drive voltage amplitude that is increased from 30 V (red) to 109 V (black) in steps of 5 V (up to 105 V, black curve at 109 V). The Duffing stiffening nonlinearity of the silicon beam can be observed in the asymmetry of the frequency response curves. b Drive amplitude voltage sweeps for the silicon beam for a forcing frequency that is increased from 493.4 kHz (black curve) to 501.0 kHz (red curve) in steps of 400 Hz. These sweeps show that the deviation from the linear regime is increased as the drive voltage amplitude and forcing frequency are increased. c Photographs of the packaged MEMS and its main electronics board. d Inertial response of the MEMS, where the sensitivity is displayed as the amplitude of the oscillation signal (in V) per unit of acceleration applied (in standard gravity g), converted to decibels (dB) using a reference level of 1 V per g (at 0 dB). e Manually colored scanning electron microscope images of a device (red: inertial mass and spring suspension, blue: anchors, green: clamped beam, yellow: inertial mass stoppers, orange: strain gages). https://www.nature.com/articles/s44172-024-00193-5

Demonstrating micro-electromechanical systems, they integrated computing and acceleration sensing for real-time gait pattern identification in a wearable attached to the foot. They found significantly improved power efficiency in the in-sensor computing system compared to traditional setups. This advancement paves the way for the widespread deployment of ML in edge computing devices.

Related Work

Past work has explored the potential of mechanical computing devices integrated with sensors, offering efficient processing of physical stimuli without the need for extensive electronic components. This approach, known as in-sensor computing, contrasts with traditional methods that rely on sensor-to-electrical signal conversion. Challenges in this field include achieving robustness against variability in gait accelerations, walking speed, and subject morphology, optimizing power consumption further, and ensuring compatibility with diverse wearable form factors.

Fabricating MEMS Devices

The micro-electro-mechanical systems (MEMS) design and fabrication process involved defining suspended inertial mass and doubly clamped beam shapes via photolithography on a silicon-on-insulator substrate, followed by deep reactive-ion etching and release through HF vapor etching. Researchers applied metallization with a chromium-gold (Cr-Au) film over electrical traces. The device layer's thickness provided both stiffness and mass, which is crucial for sensitivity to accelerations, with flexure springs ensuring displacement for accelerations while restricting transverse and rotational displacements.

Integration involved wire bonding the MEMS die to a printed circuit board (PCB) chip carrier housed within a 3D-printed enclosure for environmental protection. Electronic modules actively processed beam oscillation amplitude signals, sampling them via an analog-to-digital converter and feeding them through a leaky integrator to generate virtual node activations used in gait pattern inference. The MEMS system was tuned and trained using a ridge regression approach, ensuring real-time gait pattern detection.

Ten healthy adults underwent a gait analysis protocol using the MEMS system integrated into a wearable enclosure. Researchers instructed participants to walk on a treadmill with different gait patterns and speeds while actively sampling accelerometer signals. Data preprocessing, including downsampling and filtering, was performed to train and test the system, ensuring consistency across methods. Training involved ridge regression to obtain output layer weights, with a k-fold cross-validation procedure used for evaluation.

Power consumption analysis compared the MEMS system to a conventional implementation using an espressif systems ESP32 microcontroller. Measurements and calculations demonstrated the MEMS system's potential for significant power reduction through design optimizations, with proposed modifications aiming to achieve power levels an order of magnitude lower. Researchers pursued further reductions by eliminating feedback circuitry and exploring fully mechanical implementations with efficient drive and read-out mechanisms and mechanisms for weight adjustments to support learning.

MEMS Gait Pattern Classification

Researchers tackle classifying human gait patterns by utilizing a MEMS accelerometer capable of both sensing and computing. The MEMS device leverages the nonlinear dynamics of a silicon beam clamped at both ends, modulated by an oscillating electrostatic force. This force, applied through a suspended proof mass, varies with accelerations, influencing the beam's oscillations. The system generates multiple virtual responses by employing a feedback technique, each representing a distinct nonlinear function of the accelerations. These virtual responses are then processed to produce activation values, facilitating gait pattern inference when combined with trained weights.

Ten healthy subjects participated in treadmill walking experiments wearing the MEMS system on their left shoe. Researchers instructed the participants to alternate between different gait patterns while actively measuring their accelerations. Data collected from the MEMS reservoir computer and a conventional accelerometer were analyzed using a personalized classification approach. Researchers evaluated the system's performance using the area under the curve (AUC) of receiver operating characteristic (ROC) curves through four-fold cross-validation. The MEMS device demonstrated robustness across varying walking speeds and individual subjects, achieving competitive classification performance compared to conventional software solutions.

Despite modest sensor performance, the MEMS device, equipped with in-sensor computing capabilities, matched the classification performance of conventional systems using commercial accelerometers and sophisticated software algorithms. It demonstrates the effectiveness of in-sensor computing for complex tasks like gait pattern identification, offering potential advantages in cost, simplicity, and robustness.

Power consumption analysis revealed the MEMS system's potential for significant energy savings compared to conventional implementations. By optimizing design elements and eliminating non-essential functions, a better-optimized version of the system could achieve substantially lower power consumption. Integrating control electronics with the MEMS device and improving resonator quality offer further enhancements, enabling greater power efficiency and paving the way for practical applications in wearable devices with minimal power requirements.

Conclusion

In conclusion, integrating MEMS accelerometers capable of both sensing and computing offered a groundbreaking solution for gait pattern classification. By leveraging nonlinear dynamics and in-sensor computing, researchers demonstrated that the MEMS device exhibited robustness and delivered competitive performance in identifying various gait patterns.

Despite modest sensor performance, it matched conventional systems using commercial accelerometers and sophisticated software algorithms. The experiments highlighted its effectiveness in real-world scenarios, while power consumption analysis underscored significant energy savings potential. Overall, MEMS-based systems held promise for cost-effective, robust wearable technology with broad applications in healthcare and beyond.