In an article published in the journal npj Clean Water, researchers from India comprehensively demonstrated the challenges posed by industrial dye wastewater. Additionally, they proposed a modified design technique to effectively control influent variability and mitigate textile effluents by utilizing zinc oxide/zinc oxide-graphene oxide nanomaterial (ZnO/ZnO-GO NanoMat) based advanced oxidation processes (AOPs). Moreover, the research presented reliable prediction models using machine learning techniques to estimate water quality parameters, ensuring compliance with discharge standards.

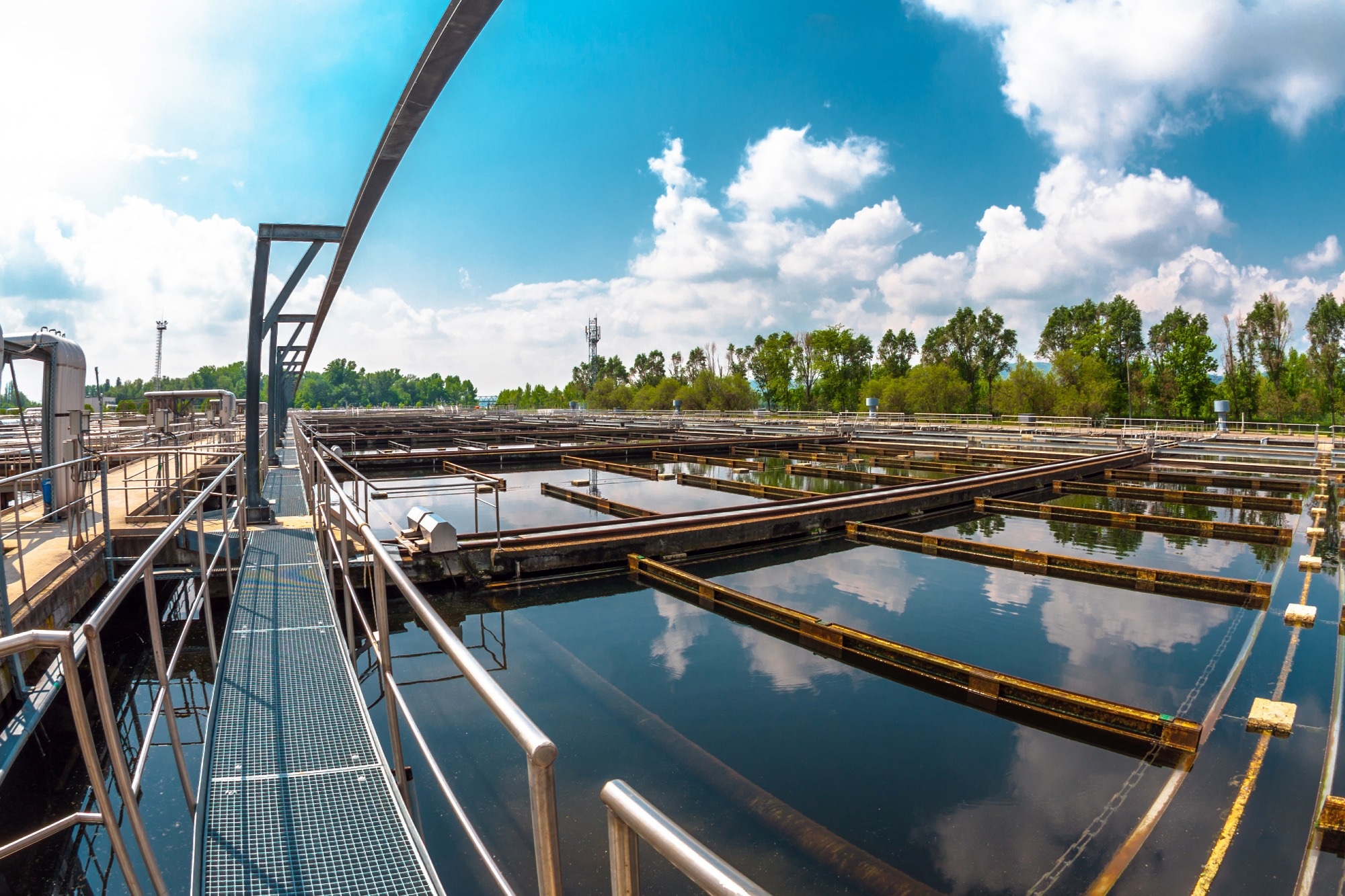

Study: Advanced Industrial Wastewater Treatment with Nanomaterial-based AOPs. Image credit: Anna Vaczi/Shutterstock

Study: Advanced Industrial Wastewater Treatment with Nanomaterial-based AOPs. Image credit: Anna Vaczi/Shutterstock

Background

Industrialized countries are facing increasing demand for textile and steel products, which unfortunately contributes to high levels of pollution through effluent discharge. Textile industries, in particular, consume substantial amounts of water for processes such as coloring, cleaning, and heat treatment. The direct discharge of textile effluents into natural water bodies or land composting sites introduces harmful substances such as colorants, chemicals, and polymers. These pollutants are carcinogenic and pose a threat to water resources.

Dye wastewater is a byproduct of textile and dyeing industries. It poses significant environmental challenges due to its vivid color, complex chemical composition, and potential toxicity. Traditional treatment methods, including coagulation/flocculation, adsorption, ion exchange, membrane filtration, oxidation, and biological treatment, play a crucial role but also have limitations in achieving complete remediation, thus requiring innovative approaches.

About the Research

In the present paper, the authors introduced an innovative approach to the treatment of textile industrial wastewater. They provided a modified design methodology for a pilot-scale micro-pre-treatment unit employing a solar-triggered AOP reactor. This reactor fulfilled two pivotal objectives: controlling influent variability and mitigating textile effluents. By adeptly managing influent variability at its source, the system ensured stable treatment performance. Furthermore, the AOP reactor effectively mitigated textile effluents, thereby rendering the discharged water suitable for reuse in various industrial applications.

The study proposed a novel combination technique integrating controlled serial processes, including primary, secondary, and tertiary treatment steps. The key features of this approach include the utilization of ZnO/ZnO-GO NanoMat-based AOPs for complete remediation of industrial-grade effluent or waste. The NanoMat-based AOPs exhibit remarkable photocatalytic activity, making them ideal candidates for environmental applications.

The researchers developed predictive models based on multi-linear regression and artificial neural networks (ANNs) to estimate water quality parameters. These models demonstrated accurate and robust prediction capabilities, ensuring compliance with inland water discharge standards (IWDS) while capturing output parameters within acceptable accuracy levels. They achieved a coefficient of determination (R-squared or R²) and adjusted R² of more than 0.90.

Moreover, the authors aimed to optimize the NanoMat dosage for maximum efficacy, evaluate the impact of varying solar irradiance on AOP performance, and assess the feasibility of scaling up the technology for industrial applications. They demonstrated that each filtration stage significantly reduced the concentration of wastewater parameters.

Research Findings

The outcomes demonstrated the successful implementation of a modified combination technique for wastewater treatment. By integrating three distinct treatment stages, the system achieved complete remediation of industrial effluent. One crucial component of this process was the ZnO/ZnO-GO NanoMat-based AOP, which played a significant role in efficiently removing pollutants from wastewater.

In addition to the modified combination technique, the developed prediction model could provide reliable estimates of water quality parameters, allowing for efficient monitoring and ensuring compliance with discharge standards. By accurately predicting pollutant concentrations, researchers could anticipate the effluent's quality with confidence, enabling better decision-making and optimization of the treatment process.

The paper also highlighted the remarkable efficiency of the NanoMat-based AOPs in degrading dyes. These AOPs exhibited consistent performance and achieved remarkable dye degradation rates, surpassing traditional methods. This efficiency was particularly notable under solar irradiance, making the process environmentally friendly and sustainable.

Furthermore, the treated effluent met stringent standards for inland water discharge. This achievement was significant as it demonstrated compliance with environmental regulations and ensured that the discharged water was safe for the environment. The successful integration of controlled serial processes and accurate prediction models was a significant step toward efficient and compliant wastewater treatment. This approach addressed the challenges posed by dye wastewater and offered a promising solution for other industrial effluents.

Applications

The proposed system has significant implications for sustainable wastewater treatment and resource conservation. In the textile and dyeing industries, manufacturers can use NanoMat-based AOPs to treat dye wastewater effectively. This helps reduce environmental impact and ensures compliance with regulations.

Moreover, scaling up this technology in urban water treatment plants promises cleaner urban water bodies. Global sustainability benefits from integrating predictive modeling and AOPs. This offers hope in addressing water scarcity and pollution challenges. Furthermore, AOPs and predictive modeling can be adapted to other industries like steel production and chemical manufacturing, expanding their potential impact.

Conclusion

In summary, the novel approach proved effective and efficient for an AOP-based treatment plant for industrial effluents. The successful integration of controlled serial processes and accurate prediction models paved the way for efficient and compliant wastewater treatment. By accurately predicting pollutant concentrations, the treatment plant was able to effectively monitor and optimize the treatment process, ensuring compliance with discharge standards.

The researchers acknowledged the limitations and challenges, including sample size, time constraints, selection bias, confounding variables, measurement error, and ethical considerations, and suggested directions for future work. They recommended enhancing the study design, increasing sample sizes, using more reliable measurement tools, and extending study durations to observe long-term effects more accurately.