In a paper published in the journal Scientific Reports, researchers explored the potential of mega-castings, large high-pressure die castings (HDPC), to replace steel sheets in automotive structures. These castings offered cost efficiency and design flexibility but posed challenges in meeting stiffness, Noise, Vibration, and Harshness (NVH) comfort and safety requirements.

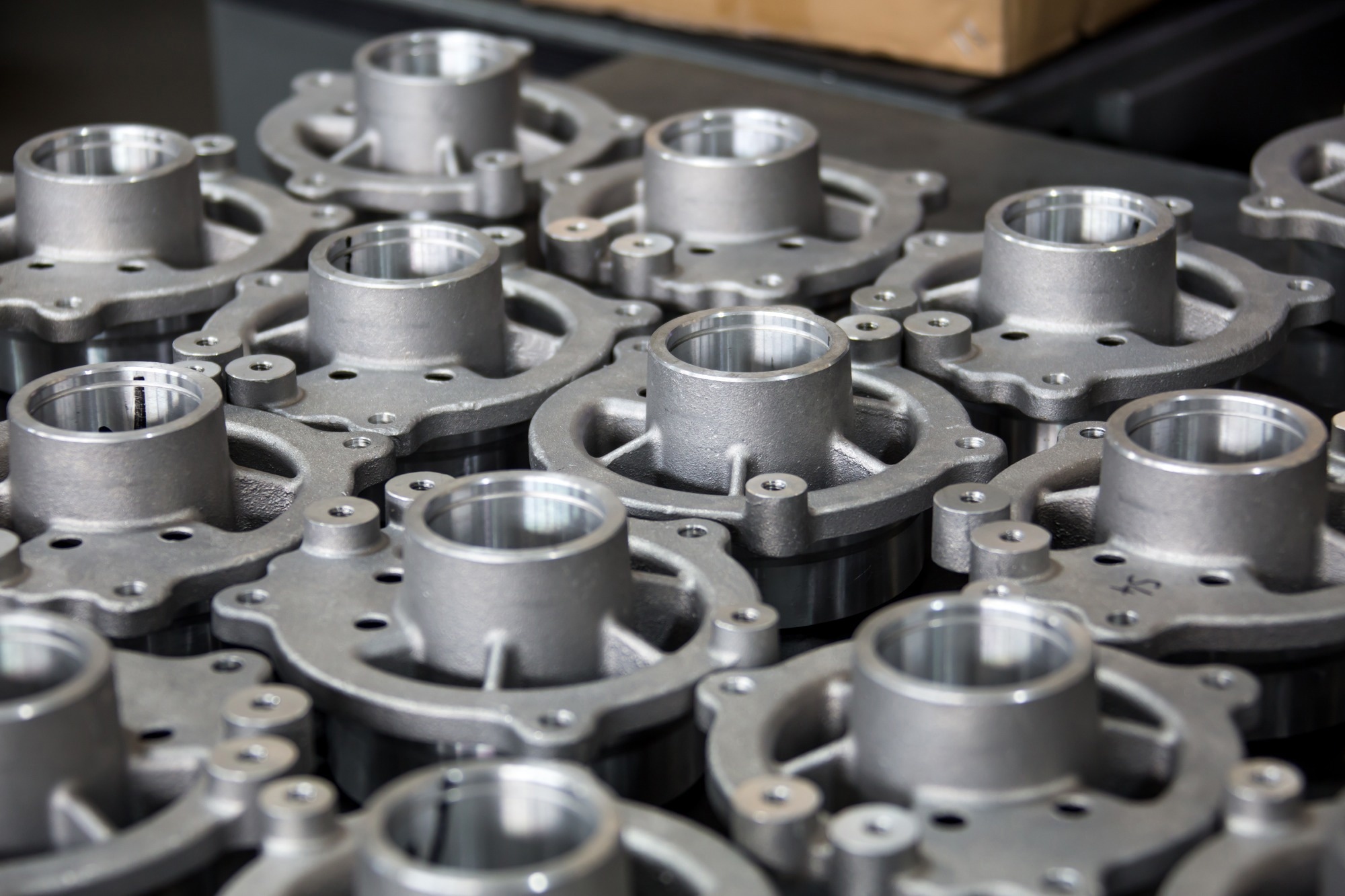

Study: Innovative Optimization of Mega-Castings for Automotive Structures: A Multidisciplinary Approach. Image credit: mehmetcan/Shutterstock

Study: Innovative Optimization of Mega-Castings for Automotive Structures: A Multidisciplinary Approach. Image credit: mehmetcan/Shutterstock

Researchers proposed a novel optimization pipeline combining topology optimization, response-surface-based (RSM) techniques, and machine learning to address this. Integrating diverse simulation data, this approach effectively balanced crash demands, castability, and structural goals, outperforming traditional workflows by generating weight-optimized designs within shorter timeframes.

Background

The automotive industry's shift towards battery electric vehicles to curb emissions intensifies the pressure on Original Equipment Manufacturers (OEMs) to reduce time and costs. While weight reduction remains a priority, integrating batteries adds weight. Mega-casting, HDPC process, presents an opportunity for body-in-white (BIW) structures due to design freedom and potential lightweight. However, challenges like limited machinery availability, manufacturing tolerances, and material quality persist. The complexity of mega-castings affects their casting quality and crashworthiness, demanding solutions beyond traditional methods. The conventional approach involves separate departmental designs, leading to non-optimal structures and iterative processes.

Multidisciplinary Load Optimization for Castings

In its initial phase, the generative design approach aims to establish a load-path conceptual design for casting structures, addressing multidisciplinary load requirements like crash scenarios. It involves two distinct design spaces: the shell design space, defined by base surfaces connected to the BIW, and the topology design space. Throughout free-size optimization, the shell element thickness varies while actively employing density-based topology optimization for the topology design.

Topology optimization actively determines the most efficient material placement within mechanical engineering, pinpointing where to place material for maximum efficiency. This study employs topology optimization to address complex design queries effectively using commercial tools and the Solid Isotropic Material Penalization (SIMP) approach. The challenge lies in handling an extensive 6-million-element design while balancing multiple linear static response optimization problems representing various load cases from statics, driving dynamics, NVH, and crash scenarios.

Linear static response optimization comprises load cases covering diverse driving conditions and NVH evaluations. However, more is needed to ensure complete satisfaction of all requirements. Crash scenarios, essential for passive vehicle safety, necessitate additional considerations. Techniques like Equivalent Static Load (ESL) or physically motivated approaches address crash complexities, as nonlinear dynamic response topology optimization poses significant computational challenges. Employing linearization techniques enables the integration of crash and NVH load cases into the multidisciplinary optimization framework.

These linearized cases are balanced and optimized using topology and free-size optimizations, incorporating casting constraints to ensure manufacturability. This intricate process aims to produce a robust, optimal design while considering diverse load scenarios and manufacturing parameters before finalizing the best candidate design for further refinements and optimization.

RSM Optimization for Pole Impact

During the second phase of the generative design process, researchers actively apply RSM-based optimization to improve the pole side-impact performance of the overall mega-casting part. Initially, the optimization focuses on vital structural sections, including individual ribs, utilizing approximately 20 design variables to define the design space. The optimization aims to minimize the maximum reaction force at the intruding pole while maximizing the remaining safe space for passengers or components, visualized within a Pareto-optimal region. The green region highlights designs with local failure, balancing structural integrity and weight considerations.

In contrast, the orange region signifies designs facing a structural collapse, emphasizing the challenge of robustness in design optimization. Clustering techniques use crash simulation data to address this complexity and minimize the need for expert evaluation. It leads to a more detailed RSM-based optimization phase that refines rib thicknesses in the critical horn region. This phase reveals distinct failure modes through clustering, emphasizing the importance of specific rib designs to ensure energy absorption and overall structural stability during a pole-side crash, showcasing improved crash behavior compared to traditional aluminum structures.

Optimizing HPDC: Structural-Casting Synergy

RSM-based optimization in HPDC is vital for balancing structural needs and casting challenges. This approach minimizes ingates by honing innate configurations and part geometry through extensive simulations and design parameterization, ensuring quicker filling times, reducing waste, and bolstering quality. It integrates structural and casting requirements in critical zones like the front horns, optimizing rib orientation, thickness, and base surfaces for crash performance.

This comprehensive strategy, rooted in RSM and clustering constraints, synchronizes casting simulations with crash mandates, delivering weight-optimized designs that meet structural and casting objectives. It showcases a unified optimization method for coupled processes validated in previous studies for its efficacy in enhancing structural integrity and releasing quality.

Conclusion

To sum up, this paper introduces a two-phase optimization strategy for lightweight structural casting parts that address diverse automotive design requirements. Leveraging topology and RSM-based optimization substantially reduces weight while meeting stringent performance criteria, notably in pole-side impact scenarios. The optimized innate design conserves materials and enhances overall part quality, surpassing conventional methodologies and establishing a pioneering multidisciplinary optimization approach.

Journal reference:

- Triller, J., Lopez, M. L., Nossek, M., & Frenzel, M. A. (2023). Multidisciplinary optimization of automotive mega-castings merging classical structural optimization with response-surface-based optimization enhanced by machine learning. Scientific Reports, 13:1, 21678. https://doi.org/10.1038/s41598-023-47937-5, https://www.nature.com/articles/s41598-023-47937-5