Microrobots, admired for their small size and agility, are vital for various in-situ treatments. In a paper published in the journal Microsystems and Nanoengineering, researchers created a unique artificial intelligence (AI) microrobot that was responsive to its surroundings without internal power, enabling real-time wireless signal transmission.

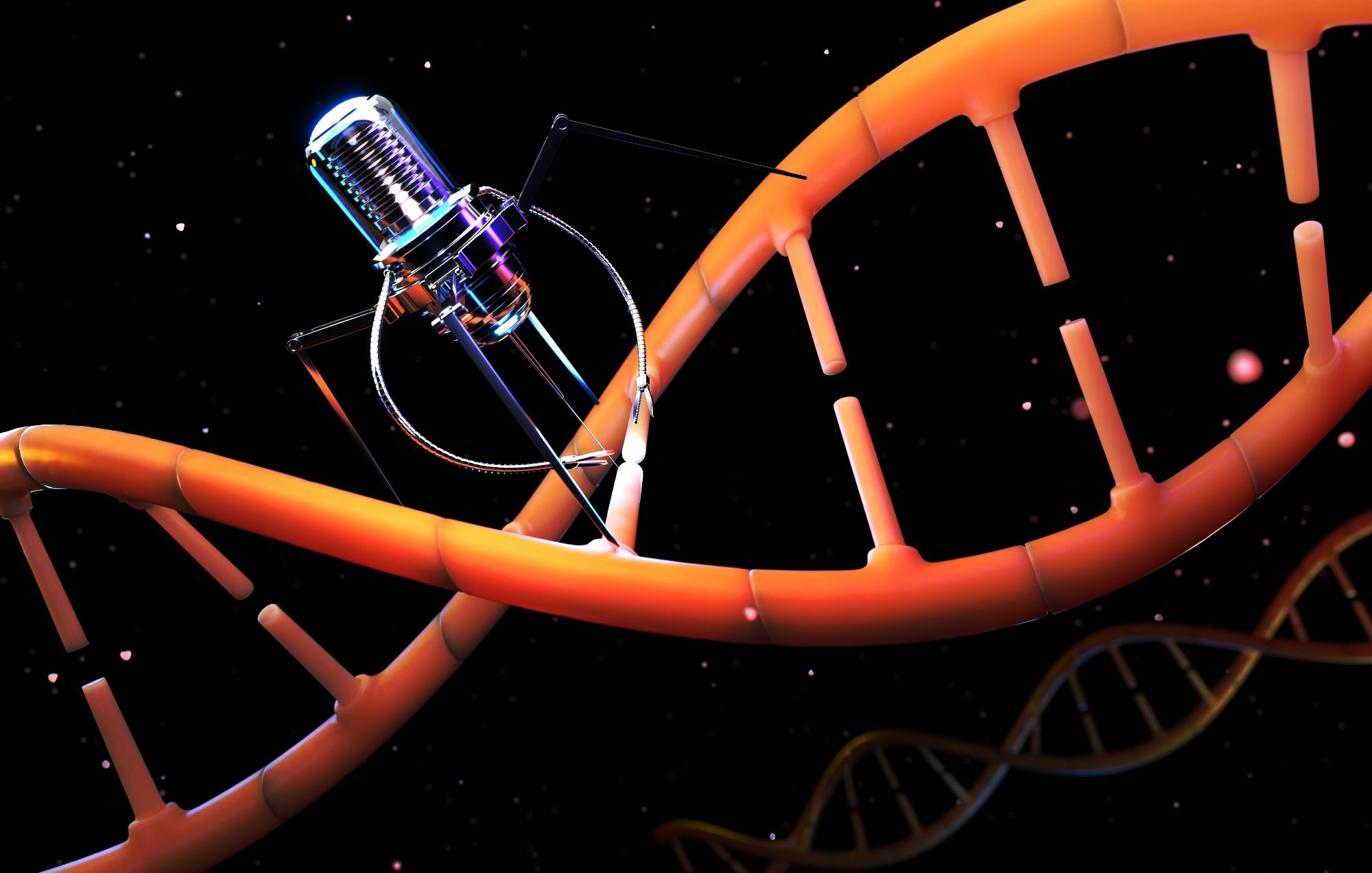

Study: AI Microrobots: Self-Sensing Innovations for In-Vivo Monitoring. Image credit: sabisaftoiu/Shutterstock

Study: AI Microrobots: Self-Sensing Innovations for In-Vivo Monitoring. Image credit: sabisaftoiu/Shutterstock

Background

Microrobots have gained significant interest for upcoming biomedical applications due to their small size and maneuverability. These microscale agents hold promise for minimally invasive in situ diagnostics, such as targeted drug delivery. Yet, functionalizing microrobots remains challenging, necessitating perception, cognition, action, and control. While prior work has focused on precise motion control using external feedback, imbuing self-perception into microrobots is crucial for localized diagnostics. Concentrated biomarkers near diseased tissues make self-sensing microrobots valuable for noninvasive, precise positioning and early disease diagnosis. These microrobots can patrol the body, detecting anomalies and continuously monitoring microenvironments. Crafting the AI Microrobot

Device Fabrication: A silicon substrate with a 300-nm silicon dioxide layer was cleaned with isopropyl alcohol, acetone, and deionized (DI) water. A sacrificial layer of 30-nm Al2O3 was applied using e-beam evaporation. Subsequently, a 30-nm silicon nitride membrane was cultivated through plasma-enhanced chemical vapor deposition, incorporating magnetic helical tails made of Fe. This was achieved using a combination of ultraviolet (UV) lithography, sputtering, and lift-off techniques. The Fe thickness and sputtering rate were optimized. Inductively coupled plasma (ICP) dry etching shaped the silicon nitride membrane into helical tail arrays. A silicon dioxide layer (100 nm) was deposited, and a lower electrode (100 nm Au) was formed. Silicon dioxide was etched by ICP to shape the head platform. A second silicon dioxide layer (100 nm) was deposited and patterned as an intermediate dielectric layer. Thermal evaporation was utilized to deposit the upper electrodes, measuring 300 nm thick and made of Au. After two hours, immersion in sodium hydroxide freed the microsensors and helical tails from the Si substrate.

Device Simulation: The device's performance was simulated using the high-frequency structure simulator (HFSS) software. This simulation considered the device's placement and the stimulated port to generate the RF magnetic field. The simulation included the three-layer sensor structure and the model calculated magnetic field distribution at various levels. Sensor responses to conductivities and permittivities were simulated by altering environmental dielectric properties.

Device Measurement: A printed circuit board (PCB) connected to a network analyzer through a Sub-Miniature-A connector facilitated measurements. The sensor directly in touch with the PCB ranged from 10 µm to the readout coil. Epoxy resin sealed the chip and protected the solution. For pH tests, different pH solutions were injected using an arc funnel. Temperature tests involved immersing the PCB end in a temperature-adjustable water bath. The network analyzer performed frequency sweeps under varying conditions.

AI microrobots for in-situ diagnosis and treatments

The concept revolves around the integration of a wireless sensor into a microrobot, enabling it to modulate the local radiofrequency (RF) magnetic field without the need for external power. The underlying principle relies on manipulating the electromagnetic field generated by the RF coil of an imaging device. As the microrobot navigates through the human body, it senses changes in the dielectric properties of its microenvironment, which are indicative of potential diseases. The integration of sensing capabilities within the microrobot is achieved through a multi-step fabrication process.

The fabrication process involves precise layer deposition, tail formation, and electrode placement. A sacrificial layer is initially deposited on a silicon substrate, followed by creating a magnetic tail and a prestressed membrane that drives the helical tail's formation. The microrobot's head platform houses the sensor, composed of interdigitated electrodes that form a closed resistance-inductance-capacitance (RLC) loop. By harvesting energy from the external RF magnetic field, the sensor can induce a current, thereby enhancing the local RF magnetic field. The resonance frequency and quality factor of the sensor are calculated, determining its sensitivity to variations in the surrounding environment.

Simulation results showcase the sensor's potential for electromagnetic field enhancement. The sensor's performance is affected by changes in environmental properties, such as conductivity and permittivity. The resonance frequency and enhancement effect are influenced by alterations in these factors, making the sensor responsive to various physiological changes. Practical experiments involving pH variations and temperature shifts demonstrate the sensor's sensitivity and potential applications in monitoring pH levels and temperature fluctuations.

The AI microrobot's movement and posture adjustment mechanisms are explored, utilizing external magnetic fields for linear and circular motion. Analysis reveals the physics of its tumbling motion, converting rotational to linear motion. This promises controlled movement. The microrobot's disease detection potential is emphasized, using enhanced electromagnetic imaging for early disease spotting. Future goals encompass material enhancements for targeted molecule detection. Envisioned is a network of AI microrobots for active body monitoring and potential treatment.

Conclusion

In summary, a self-sensing wireless AI microrobot was created for noninvasive in vivo monitoring. Comprising a head sensor and magnetic helical tail, it detects environmental changes through enhanced electromagnetic imaging signals. Driven by external fields, the sensor circuit draws energy from RF magnetic fields; its tuning is influenced by local conditions. The microrobot's controllable movement and self-sensing capabilities hold promise for challenging-to-access body monitoring alongside electromagnetic imaging. Integrating passive sensing suggests the potential for noninvasive wireless in situ monitoring and future disease diagnosis. The fabrication process allows mass production and functional coatings for diverse applications.